Measuring instruments are essential tools across construction, manufacturing, engineering, and maintenance industries. From simple tape measures to advanced laser devices, accurate measurement plays a key role in quality and efficiency. With technology evolving rapidly, many professionals now ask an important question: are digital measuring instruments better than manual ones? The answer depends on usage, accuracy needs, and work environment. Let’s explore the differences to understand which option suits your needs best.

Understanding manual measuring instruments

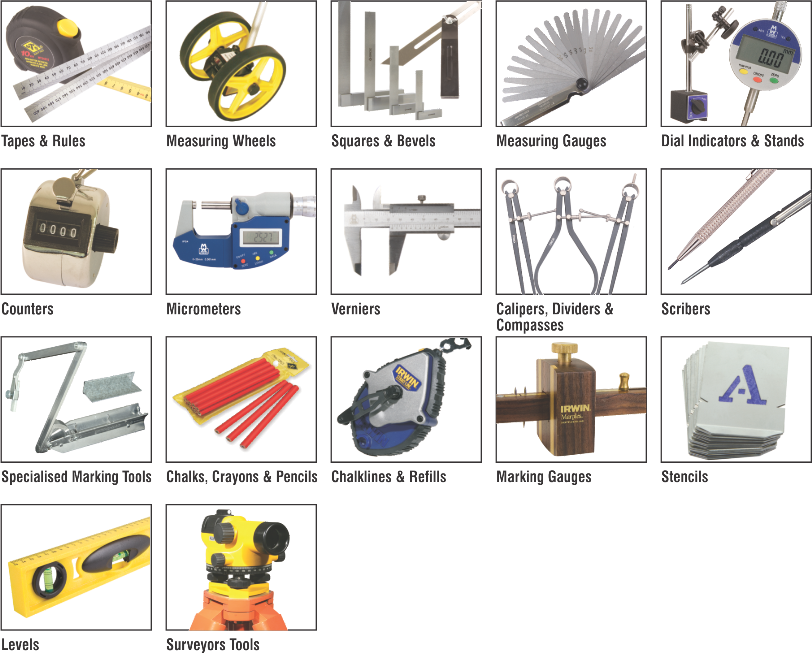

Manual measuring instruments include tools such as tape measures, vernier calipers, micrometers, spirit levels, and rulers. These tools have been used for decades and are still widely trusted for basic measurement tasks. They do not require batteries or electronic components, which makes them reliable in rough or remote working conditions.

Manual instruments are generally affordable and easy to use. They are ideal for tasks where extreme precision is not critical or where measurements are taken frequently in harsh environments. Many skilled professionals still prefer manual tools due to their simplicity and long lifespan.

What are digital measuring instruments?

Digital measuring instruments use electronic sensors and digital displays to provide measurement readings. Examples include digital calipers, laser distance meters, digital micrometers, and electronic multimeters. These tools are designed to deliver fast, precise, and easy-to-read results.

Digital instruments are especially useful in professional and industrial settings where accuracy, speed, and data consistency are important. Many digital tools also include features like data storage, unit conversion, and wireless connectivity.

Accuracy and precision comparison

One of the biggest advantages of digital measuring instruments is accuracy. Digital tools reduce human reading errors by displaying exact values on a screen. This is particularly useful for fine measurements where even a small mistake can affect product quality or safety.

Manual instruments can also be accurate, but they depend heavily on user skill and experience. Reading scales or markings incorrectly can lead to measurement errors, especially in low-light conditions or fast-paced environments.

Ease of use and efficiency

Digital measuring instruments are generally easier and faster to use. Clear digital displays make readings quick and straightforward, saving time during repeated measurements. Features such as automatic zeroing and instant unit switching further improve efficiency.

Manual tools require more attention and skill. While experienced workers can use them efficiently, beginners may find them slower and harder to read. However, manual tools are still effective for simple measurements and routine tasks.

Durability and maintenance

Manual measuring instruments are known for their durability. With no electronic parts, they can withstand dust, moisture, and rough handling better than many digital tools. Maintenance is minimal, and they often last for many years.

Digital measuring instruments, while advanced, require proper care. Batteries need replacement, and electronic components can be sensitive to extreme conditions. However, modern digital tools are increasingly designed with rugged casings to handle industrial environments.

Cost considerations

Cost is another important factor. Manual measuring instruments are generally more affordable and suitable for small businesses or basic applications. Digital instruments usually come at a higher price due to advanced features and technology.

However, the higher cost of digital tools can be justified in industries where precision, speed, and productivity directly impact performance and profits.

Which one should you choose?

Digital measuring instruments are better for tasks that demand high accuracy, speed, and consistency, such as quality control, engineering, and advanced construction work. Manual measuring instruments remain a practical choice for basic measurements, outdoor work, and environments where simplicity and durability matter most.

In many cases, professionals use both types depending on the task. Having the right tool for the right job ensures efficiency and accuracy.

Conclusion

Digital measuring instruments offer superior accuracy, ease of use, and advanced features, making them ideal for modern professional applications. Manual instruments, however, remain reliable, durable, and cost-effective for everyday use. Rather than choosing one over the other, the best approach is to select the measuring instrument that matches your specific work requirements.

Write a comment ...